Deep Dissection of Komshine FX39 Trunk Fusion Splicer Introduction: There are many cable connection

Existing fiber optic connection technology(1) Temporary connection (cold connection): A method in which the optical fiber is cut into the required section with an optical fiber tool, and then inserted into the SC cold connector to fix it. The advantages are convenience, flexibility and low cost. The disadvantages are poor signal transmission quality and large loss, easy to break and easy to fail.

(2) Active connection: the use of fiber connecting devices to connect fiber lines has the advantages of flexible joints and convenient exchange of connection points. The disadvantage is that the loss and reflection of this connection method are large.

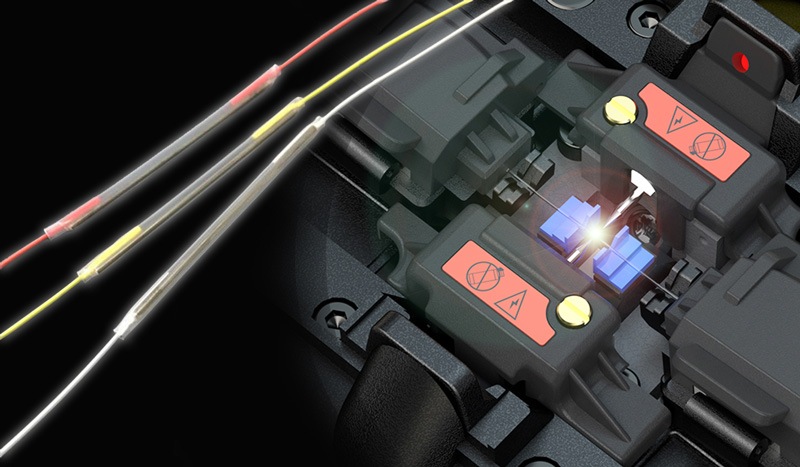

(3) Fixed connection (hot fusion): a fiber splicing method in which the end face of the optical fiber to be connected is melted and connected by the method of heating by a fusion splicer. Since the 1990s, it has become the optical fiber connection method that has been favored by communicators.

Main function modules of FX39

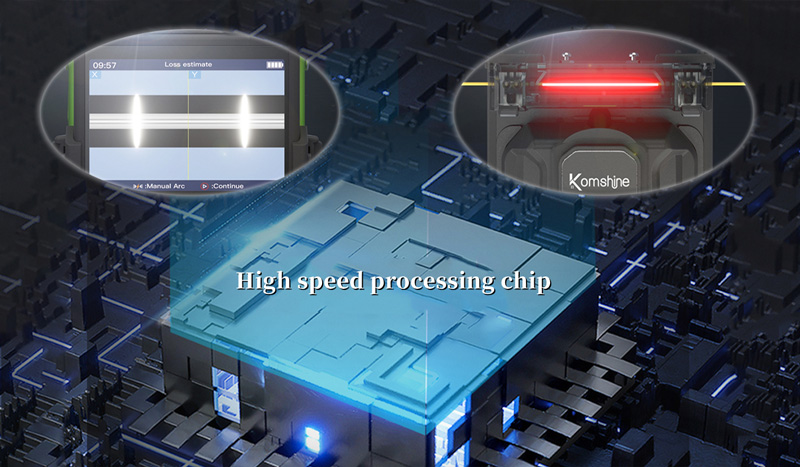

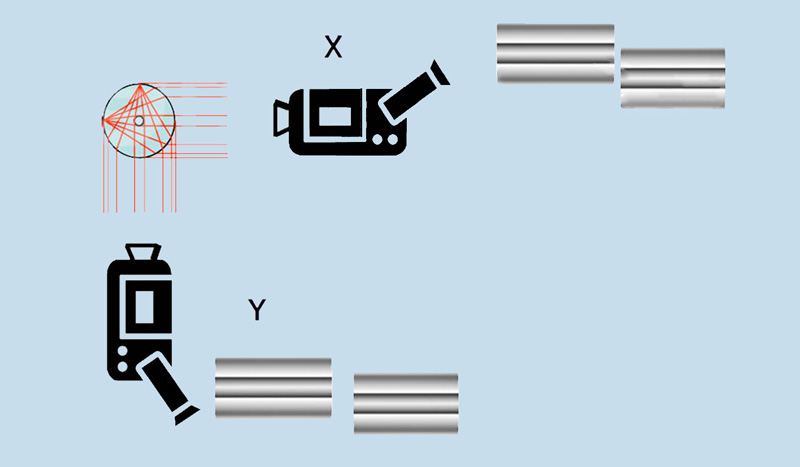

(1)Vision subsystem

The vision subsystem collects the two transmitted information through the image acquisition card. After image processing, feature extraction, and three-dimensional calculation, the optical fiber position information is obtained and the positioning subsystem is controlled to achieve rough adjustment; The video signal is collected and real-time image edge detection is performed. At the same time, the computer image recognition technology and computer intelligent control technology are used to cooperate with the mechanical transmission system to complete the gap and core alignment process of the two optical fibers with high precision. After confirming that the optical fibers are in the best position When the discharge subsystem discharge welding。

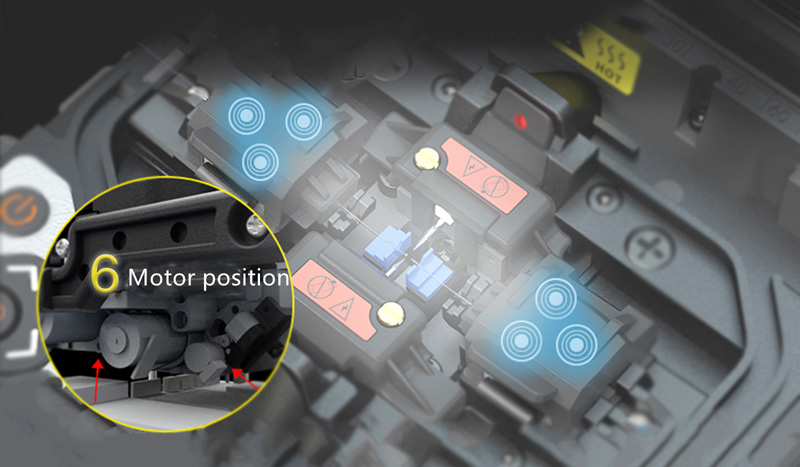

(3)Precision Positioning Subsystem

① Mechanical system

The core adjustment mechanism of a general optical fiber fusion splicer only needs 3 degrees of freedom, if in order to realize the coupling of the fiber and the wave-guide device, 6 degrees of freedom should be required. In the FX39 centering mechanism, the translation mechanism is realized by a precision-grinding sliding screw and a high-precision linear slide rail, and the rotating mechanism adopts a precision worm gear structure with a gap-free assembly process.

② Drive System

FX39 is driven by stepper motor. The stepper motor is small in size, simple and flexible in control mode. It adopts subdivided steps, which eliminates resonance factors, has low motion noise, does not have a large system load, and does not lose steps, and can achieve high control accuracy. Both the motor driver of FX39 and the motor controller of the rotating part can meet its precision requirements.

Using the principle of arc discharge, the FX39 central control chip controls the discharge of the discharge circuit. After the optical fiber is positioned, the control parameters of the default setting connection mode are transferred from the memory to control the power of the discharge, the number of discharges, and the stepper motor during the discharge process. Advance the situation. In each mode of action, as long as the relevant parameters are automatically loaded to complete. The heating furnace heats the heat-shrinkable tube according to the set temperature. The single-chip microcomputer controls the temperature and timing. After the heat-shrinking is completed, the fan is started to cool. In the fast mode, the FX39 heats the 40mm heat-shrinkable tube for only 16 seconds. Not only that, the 7800mAh high-capacity lithium battery and the electrode with 5000 times of discharge life used by FX39 support the stable operation of the discharge system throughout the process.